Product Description

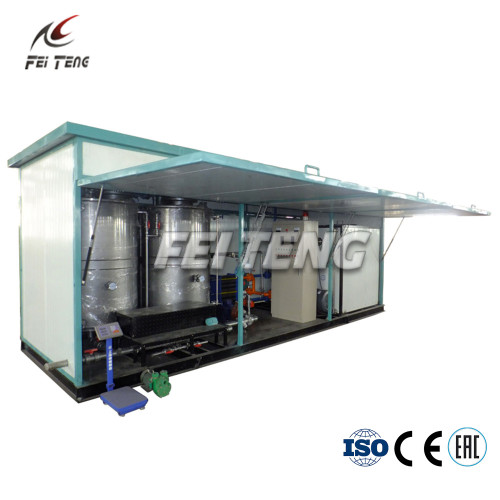

Product Description Carbon Steel Easy Transfer Bitumen Emulsion Machine For Road Maintenance Description Emulsified asphalt is mainly used for road upgrading and maintenance, such as stone chip sealing layer, and there are a variety of unique and other irreplaceable applications of asphalt materials, such as cold mix and slurry sealing layer. Emulsified asphalt can also be used in the construction of new roads, such as sticky layer oil, permeable layer oil, etc. Features 1. To control the rate of the bitumen and the soap water, the flows for bitumen and soap water are controlled individually, the bitumen is pumped with gear pump with flowmeter, while the soap water is pumped by centrifugal pump with electric valve and flowmeter, also it is equipped online bitumen content analysing system to check the content of the bitumen. 2. Stainless steel soap water tanks, pipes and valves, which is highly resistant to heat and corrosion. 3. Stainless steel thermal insulated soap water tanks with heat transfer oil pipe inside ensures rapid heating. 4. Heat transfer oil insulated all stainless steel rotor and stator emulsion colloid mill driven by 37 kW motor, multilevel shearing and high quality finished products. 5. High viscosity heat insulated bitumen pump equipped with safety valve. 6. Independent control room, unique PLC temperature and rate control system, visual operation, easy to use. 7. The whole system is built in a container and is suitable for sea shipping.. Components Based on the working principle of the plant, the plant is mainly composed of soap water system, bitumen system, colloid mill system, cooling system, control system, pipes and valves. 1. Bitumen System Bitumen system includes bitumen pump, flowmeter and valves. With the flowmeter, the bitumen pump is accurately controlled. 2. Soap water system Soap water system mixes and transfers the soap water. Mixing system includes water pump and soap water mixing tank. Transferring system includes pump, flowmeter, filter, electric valve and one-way valve. Soap water tank with level meter ensures accurate measurement and formulation of the soap water, and the soap water is heated by the heat transfer oil pipe and timely monitored by the thermometer. 3. Colloid mill The mill adopts multilevel rotor and stator bits, which has high speed shearing. Driven by 37 kW motor with 2940 rpm rotate speed. 5 and 6 rows of bits ensure the bitumen has excellent particle range. Heat transfer oil heated, adjustable gap between rotor and stator. 4. Cooling system Plate heat exchanger with 10 m2 cooling area. 5. Control system The system is controlled by PLC; with manual/auto controlling modes optional. Its online bitumen content analysing system monitor the rate of the bitumen and soap water timely, ensure the output products meet the requirement of the operator.

Loading ..

Company Profile

| |

Business Type: |

|

| |

Comapany: |

Dezhou feiteng road construction equipment co., ltd. |

| |

Year of Establishment: |

2013 |

| |

Address: |

Wucheng |

| |

City: |

Shandong dezhou |

| |

Zip/Postal: |

253000 |

| |

Country: |

China |

Company Overview

In 2005, Dezhou Feiteng Road Construction Equipment Co. got its start in the manufacturing of bitumen equipment. Since then, we have produced thousands of pieces of high-performance bitumen production machinery, including bitumen melting equipment, bitumen equipment, bitumen storage and heating tanks, bitumen processing equipment, and bitumen distributors.

Utilizing extensive experience and industry knowledge, we employ advanced equipment to carry out large scale metal fabrication processes, including laser cutting, welding, plate rolling, and painting. Currently, we have the capability to produce more than 200 sets of bitumen equipment each year.

Our bitumen equipment is widely applied in the production, management, storage, and transportation of bitumen for use in road construction and maintenance. We offer asphalt/bitumen mixing plants (asphalt batching plants), asphalt/bitumen recycling plants, and asphalt/bitumen emulsion plants.

.